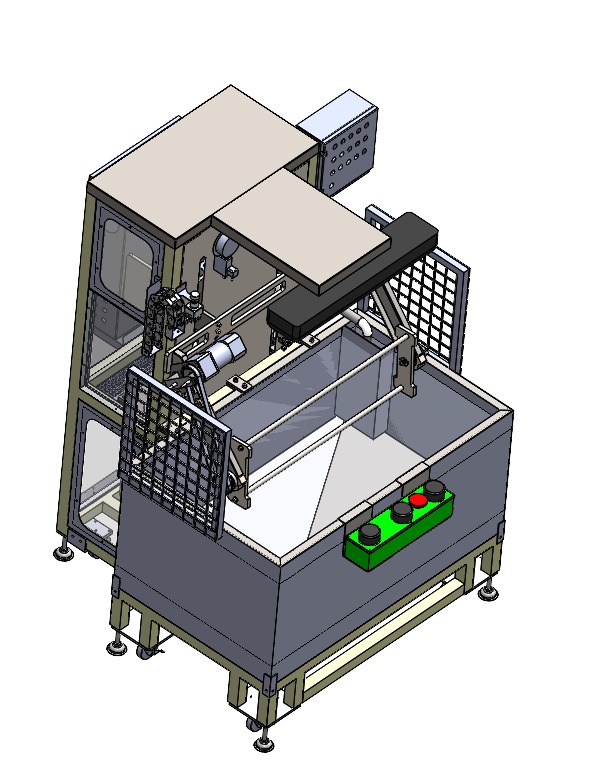

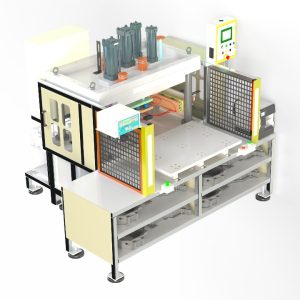

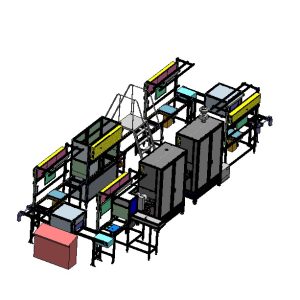

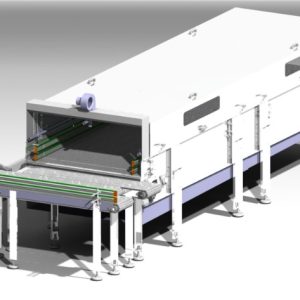

Wet Leak Testing / Dipping Testing Machine

Wet Leak Testing, also known as Dipping Testing, is a widely used method for detecting leaks in sealed components across industries such as automotive, HVAC, medical devices, and electronics. The process involves sealing the part and pressurizing it with air or nitrogen, then submerging it in a water tank. If a leak is present, air bubbles form at the leak site, providing a clear visual indication of the problem. This method is cost-effective, simple to implement, and ideal for small to medium production volumes. While it offers visual confirmation of leaks, it has some limitations, such as sensitivity to very small leaks and dependence on operator observation. Modern automated systems can improve efficiency by incorporating robotic arms, high-speed cameras, and leak detection software, making it easier to integrate into production lines.